Services presentation

With more than three decades of practical experience and unique know-how in the field of micromechanics, we are able to meet the most complex challenges in the production of mass-produced parts.

Our mastery of stamping and machining techniques guarantees our customers tailor-made solutions, perfectly adapted to their needs in a wide range of sectors, including watchmaking, connectors, electronics, appliances and medical devices.

We are committed to delivering results of impeccable quality, while building lasting relationships with our customers based on trust and excellence.

Stamping

At BG Concept, we specialize in precision progressive stamping.

Stampmaking is an increasingly rare profession, requiring specialized expertise and long experience.

Progressive stamping, also known as progressive stamping, is a production tool that enables several successive operations, such as cutting, bending or stamping, to be performed on a material in a single sequence.

Progressive stamping stands out for its speed, precision and cost-effectiveness in mass production.

It represents an efficient and reliable solution for industries requiring high-quality components with high production volumes.

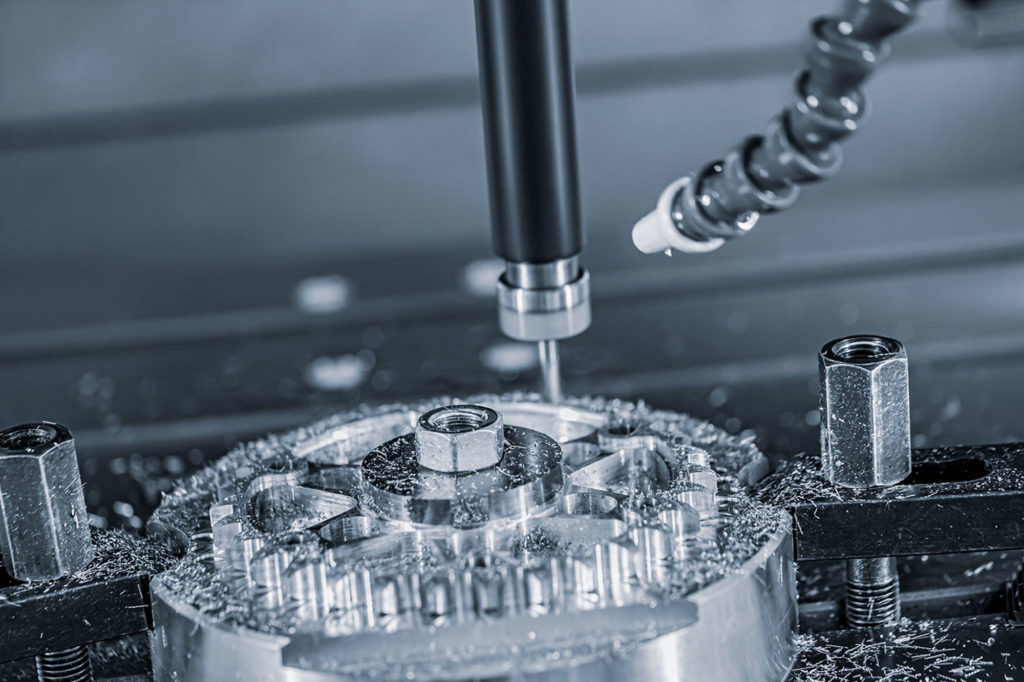

Machining

BG Concept is your trusted partner for the design and production of custom micromechanical parts, with a total commitment to quality and precision.

Thanks to our state-of-the-art equipment and recognized know-how, we are able to produce micromechanical parts that meet the requirements of the most demanding sectors.

From small to large production runs, our equipment enables us to meet our customers’ expectations.

Microspeed

Experience at the service of users

The MicroSpeed is a non-contact flatness measurement instrument designed to guarantee speed, precision and efficiency in your workshop inspection operations.

Its compact design and intuitive operation make it indispensable for reliable, repeatable results.

Users can monitor their parts during the various phases of the manufacturing process to guarantee quality.