Our machining services in Switzerland adapt to your specific needs, even for your most delicate projects.

Highest precision for your micromechanical parts

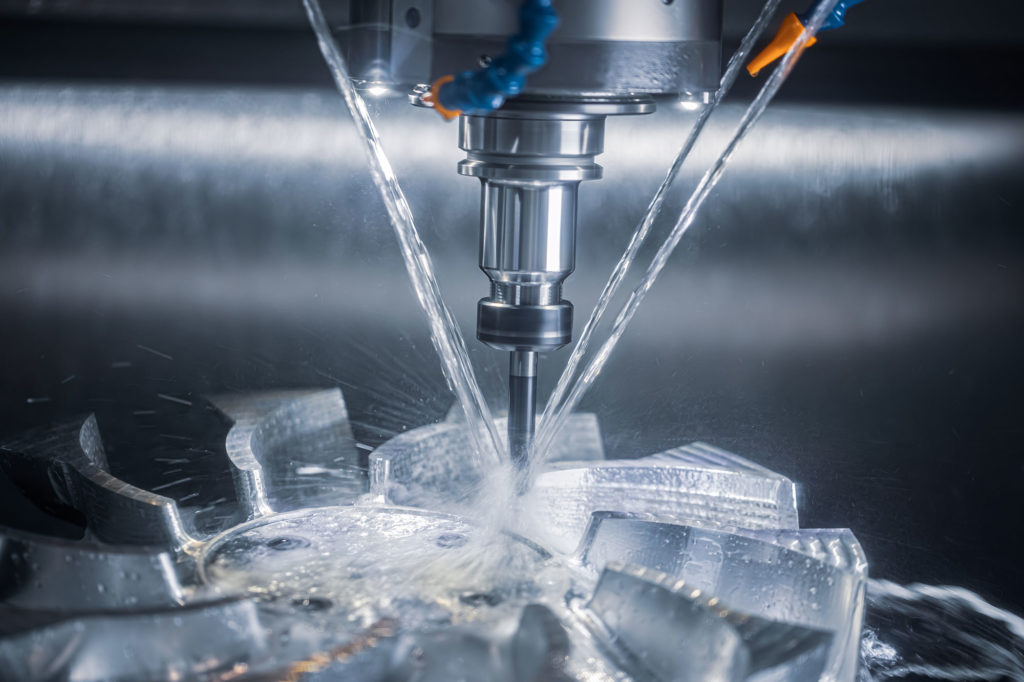

Machining is a manufacturing technique that creates mechanical parts from raw materials such as metal or plastic, using high-precision machine tools.

This process is essential in sectors such as connector technology, watchmaking, electronics, medical devices and aeronautics.

We can machine parts from steel, aluminum, copper, titanium and plastic.

CNC machining centers, screw machines, levelers and grinders are an integral part of our machinery.

The parts are inspected during manufacture and then at the final inspection stage.

Our machining processes guarantee parts for the most demanding sectors.

How do we work?

Our machining services can be adapted to your needs, whether for small or large production runs. Contact us today to discuss your project!

Send us a request including a drawing of the part, the quantity required and the lead time.

Identify machining steps to optimize the process and ensure quality.

Machine tool selection and programming, and setting of machining parameters.

Execution of machining processes to precise dimensions, required series and tightest tolerances.

In-process self-monitoring and final quality control to ensure your complete satisfaction.

Tailor-made service

BG Concept is your trusted partner for the design and production of custom micromechanical parts, with a total commitment to quality and precision.

Our services

BG Concept combines 30 years of expertise in micromechanics, stamping and machining in Switzerland, offering tailor-made solutions for producing precise miniature parts, transforming materials and designing mechanical components for the most demanding sectors.

Tailor-made solutions for every customer

Machining processes are essential in sectors such as aerospace, automotive and precision engineering, where every part must conform to the required dimensions and tolerances, while complying with strict standards.

High-precision manufacture of micro-parts for complex, reliable systems.

Mass production of small, complex automotive components.

Production of components used in miniature connectors.

Meticulous machining of high-precision watch parts to tight tolerances.

Manufacture of microcomponents used in sensors.

Medical technology requires the manufacture of complex, high-quality parts.

Frequently asked questions

For a quotation, please send us a request including :

Yes, we work with partners for heat treatment, polishing and surface treatment.

Delivery times depend on the project. We will provide you with an estimate once we have drawn up a quotation.

Machining is an essential micromechanical technique that includes several methods, each with its own specific features and applications. The main types of machining include milling, turning, drilling and grinding.

Milling: This method uses a numerically controlled machine to remove material and obtain the desired shape. Thanks to our know-how, we are able to produce complex parts with great precision.

Turning: Turning is the process of rotating a workpiece on an axis while a cutting tool removes the material. This technique is particularly suited to producing screws, bars and other cylindrical products.

Drilling: Used to create holes in a workpiece, drilling is often combined with other machining operations to meet specific project requirements.

Grinding: This method enables very tight tolerances to be achieved, thanks to precise control of the cutting tool. The technology used here ensures a high-quality finish.

Each type of machining requires specific skills and proven experience. Our company makes this expertise available to guarantee services that meet our customers’ expectations and industry standards.

The four basic machining operations are milling, turning, drilling and boring. Each of these methods plays a crucial role in the manufacture of precise mechanical parts, adapted to the diverse requirements of industrial sectors.

Milling: This operation involves removing material by cutting with a rotating tool. It can be used to shape parts in a variety of shapes and sizes, while guaranteeing remarkable precision.

Turning: Using a lathe, this method creates cylindrical parts by rotating the material on a fixed axis. It is particularly effective for producing screws or bars.

Drilling: Drilling is essential for creating holes in parts. This can be done on a variety of materials, offering great adaptability to order requirements.

Reaming: This operation refines the internal dimensions of an existing hole to achieve the shape and precision required by the project. It requires a mastery of tools and methods to guarantee a result in line with specifications.

These machining operations are carried out using advanced technologies and precise numerical control, ensuring the development of high-quality products.

5-axis machining is an advanced technique that uses machining centers equipped with machine tools capable of moving on five different axes simultaneously. This approach makes it possible to produce parts with high geometric complexity, while guaranteeing outstanding precision.

In a traditional machining process, machine tools generally operate on three axes (X, Y and Z). However, the addition of two extra axes (A and B) in 5-axis machining enables the part or tool to be tilted and rotated. This opens up the possibility of working on inclined surfaces or complex shapes without having to reposition the part, which considerably reduces manufacturing time and increases efficiency.

The machine tools used in 5-axis machining are generally numerically controlled, guaranteeing exceptional repeatability and precision. Thanks to this technology, it is possible to produce parts with very tight tolerances and an optimum surface finish.

This method is particularly popular in demanding sectors such as the aerospace, medical and automotive industries, where each part must meet strict specifications. By integrating 5-axis machining into our processes, our company is able to respond to the most complex design challenges, while offering tailor-made solutions to our customers. Thanks to our expertise, we can guarantee high-quality products tailored to the requirements of each project.